Crusher Isolate Vibrations From Structures

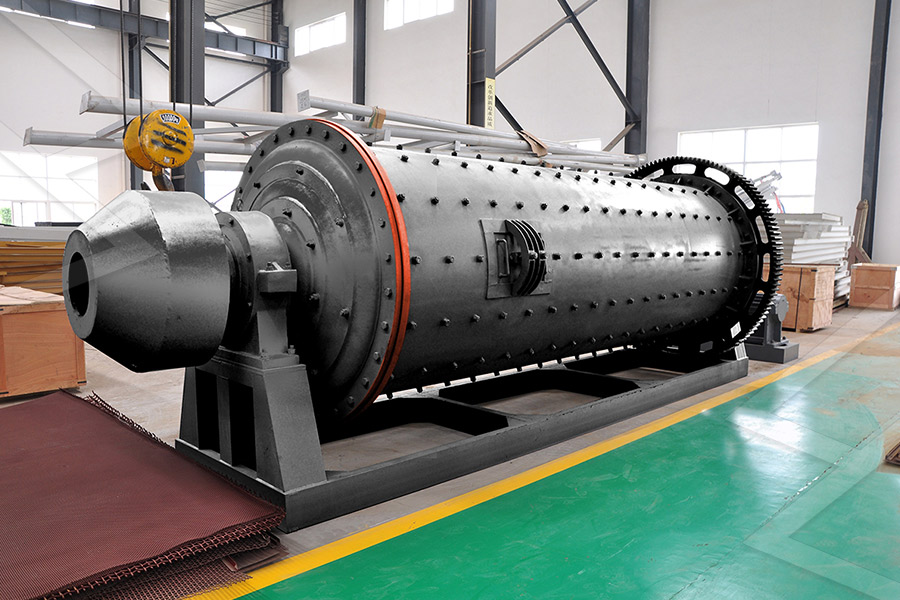

(PDF) Vibration Test and Shock Absorption of Coal

2020年10月28日 This study showed that the vibration displacement of a coal crusher with a spring vibrationisolation system met the code requirements, 2025年2月11日 Since passive vibration isolation is used to solve the vibration problem of the underwater crushing device is difficult to isolate the lowfrequency vibration effectively, and Research on the controller of an active vibration isolation unit for 2024年10月1日 This research aims to explore the effects of these factors on the productivity and horizontal vibration characteristics of gyratory crushers to provide a scientific theoretical basis Analysis and optimization of vibration characteristics of gyratory In addition, the methods of preventing vibration of the investigated objects such as bucket wheel excavators, roller mills, crushers, load carrying structures are presented Keywords: structural Investigations of Structural Vibrations Problems of High Among the three vibration isolation techniques, the passive isolation strategy is for the most part utilized in the many crushing plants or in the structure of the VIBRATION MONITORING AND CONTROL ON A of a coal crusher Spring Support of Coal Crusher Foundations in Power Plants Coal crushers of all types, such as ring granulators, pulverizers, hammermills, rotary breakers, roll and jaw crushers, can often cause signifi cant and unacceptable vibrations in theirSpring Support of Coal Crusher Foundations in Power Plants

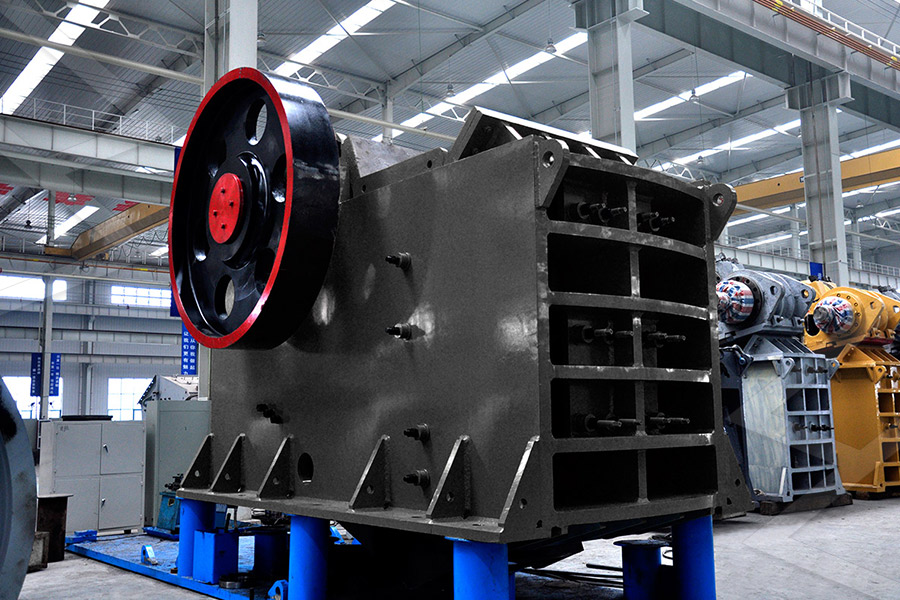

New design of the crusher supporting structure

Download scientific diagram New design of the crusher supporting structure from publication: Investigations of Structural Vibrations Problems of High Performance Machines High performance 5 In many cases, manufacturing and quality control must coexist in workcells or in close proximity to one another For certain machines, the permissible amplitudes of machine foundation vibrations in a manufacturing environment are very low It often is very difficultFoundation Isolation Solutions for Equipment MachinesVICODA GmbH Base isolation for SEYITOMER THERMAL COAL 9 Mar 2016VICODA has been chosen as the supplier for the base isolation system of 3 coal crusher in the SEYITÖMER coal fircoal crusher isolationContribute to sbmcrushers/sbmchina development by creating an account on GitHubsbm isolate crusher vibrations from structuresmdKINETICSTM Control of Vibration, Shock, and StructureBorne Noise 2,500 lb (1134 kg) loads, we can load it between 1,000 and 4,000 lbs (454 and 1814 kg), and the performance will be the same Rubber, springs or air mounts don’t do that Fiberglass is made inKINETICSTM Control of Vibration, Shock, and StructureBorne 2020年10月28日 The vibration displacements and velocities of the structure, coal crusher body, and vibrationisolation platform were Multistorey industrial structure vibration often occur when import large (PDF) Vibration Test and Shock Absorption of Coal

.jpg)

Mitigation of seismic and vibration responses for structure

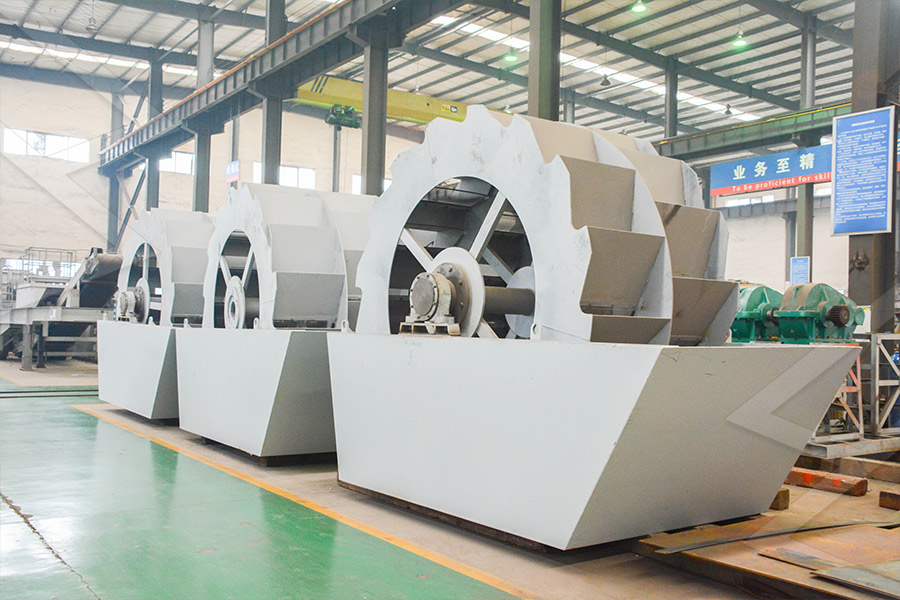

The abovementioned threedimensional isolation bearings are mainly used for building foundation isolation or reduction of equipment vibration They may not be able to meet the vibration isolation requirements for structureequipment coupled systems [29], for example a smaller stiffness of air springs can cause larger vertical displacements in large equipment2020年7月24日 A vibration isolation structure of coal crusher house Figures available via license: Creative Commons AttributionNonCommercial 40 International Content may be subject to copyright (PDF) Research on Structural Design of Coal Crusher 2022年4月19日 Thus, the Fabreeka team developed a successful solution to prolong product and machine life using our trademark impact shock and vibration isolation solution Fabreeka Pad As the original preformed fabric reinforced elastomeric pad, the Fabreeka pad is exceptionally suited for impact shock control and vibrations isolationVibration Isolation and Impact Shock Reduction in Mining 199 a b c S,mm C G Q = 500/100 kN Foundation of jaw crusher Concrete floor G7 G4 Fig 1Building housing primarycrushing unit a) section; b) foundation of SMD60A jaw crusher; c) settlement curves of column foundations in axes G4 and G7 Dynamic loadVibration Insulation for Jaw Crushers ― an Effective Means of 2020年9月15日 The vibration displacements and velocities of the structure, coal crusher body, and vibrationisolation displacement of a coal crusher with a spring vibrationisolation system met the code (PDF) Vibration Test and Shock Absorption of Coal Crusher Chambers 2025年2月19日 Rock crushers play a crucial role in various industries, including mining, construction, and aggregate production However, they also contribute significantly to noise pollution, affecting workers, nearby communities, and the overall environment Whether utilizing stationary or mobile crushers, implementing effective rock crusher noise reduction strategies is Noise Pollution from Rock Crushers: How to Minimize It

Understanding Vibrations in SteelFramed Structures

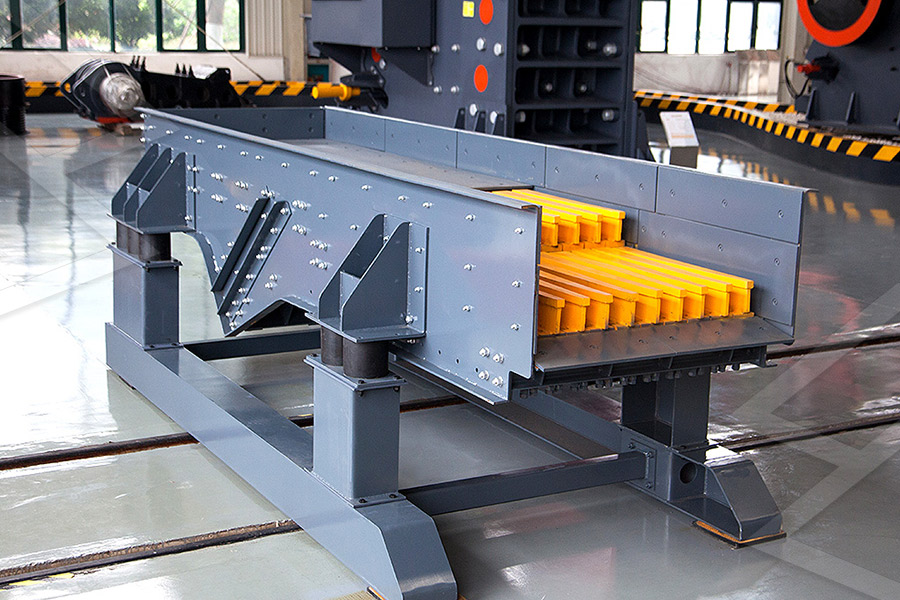

Vibrations in steelframed structures, particularly those caused by human activities, are a critical serviceability concern in structural design Thus, the natural frequency of the simply supported steel beam is approximately 2524 isolate them from vibrations were incorporated as well The above actions extended the life time of the mills significantly and allowed to operate the equipment safely Figure 8: Reinforcement of separator channel 23 Prevention of vibrations of the jaw crusherInvestigations of Structural Vibrations Problems of High %PDF15 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/ExtGState >/XObject >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 59532 84192 Structural Vibration and Ways to Avoid It WoodA field vibration test was conducted on the coal crusher chamber of a thermal power plant to evaluate its vibration performance The vibration displacements and velocities of the structure, coal crusher body, and vibrationisolation platform were tested The vibration Vibration Test and Shock Absorption of Coal Crusher Chambers 2024年9月13日 These hammers use special vibrationdampening bushings that isolate the hammer from the excavator, reducing the impact on both the machine and the surrounding environment The result is smoother operation, increased operator comfort, and reduced risk of damage to nearby structures or underground utilitiesHydraulic Breaker Hammers: Reducing Noise and Vibration2020年6月24日 Thus, the transmissib ility of the vibration isolation model is defined as the ratio of the magnitude of the force transmitted to the exciting fo rce [32–37]:Vibration Diagnosis of Sand Units in a Stone Crusher Plant: An

VIBRATION ANALYSIS OF STRUCTURES

32 The Pulse Report – Jaw Crusher Machine 29 33 The Pulse Report – Steel Flat 30 34 The Pulse Report – Composites 32 121 Vibration Structures experiences vibration to some degree and their design generally requires considerations of their Fabreeka pad is the original preformed fabric reinforced, elastomeric pad developed in 1936 The properties of the Fabreeka cotton duck pad are exceptionally suited for impact shock control, vibration isolation and structureborne noise insulation Fabreeka pad can Fabreeka® Preformed Fabric Pad Fabreeka Vibration Isolation Crusher Sizer Support structure Cantilevered Frame Crushed lime stone Feeder unit the supporting structure, and installation vibration isolation pad in between the overhand motor and structureVIBRATION PROBLEMS OF THE PRIMARY LIMESTONE CRUSHER of a coal crusher Spring Support of Coal Crusher Foundations in Power Plants Coal crushers of all types, such as ring granulators, pulverizers, hammermills, rotary breakers, roll and jaw crushers, can often cause signifi cant and unacceptable vibrations in theirSpring Support of Coal Crusher Foundations in Power PlantsDownload scientific diagram New design of the crusher supporting structure from publication: Investigations of Structural Vibrations Problems of High Performance Machines High performance New design of the crusher supporting structure5 In many cases, manufacturing and quality control must coexist in workcells or in close proximity to one another For certain machines, the permissible amplitudes of machine foundation vibrations in a manufacturing environment are very low It often is very difficultFoundation Isolation Solutions for Equipment Machines

coal crusher isolation

VICODA GmbH Base isolation for SEYITOMER THERMAL COAL 9 Mar 2016VICODA has been chosen as the supplier for the base isolation system of 3 coal crusher in the SEYITÖMER coal firContribute to sbmcrushers/sbmchina development by creating an account on GitHubsbm isolate crusher vibrations from structuresmdKINETICSTM Control of Vibration, Shock, and StructureBorne Noise 2,500 lb (1134 kg) loads, we can load it between 1,000 and 4,000 lbs (454 and 1814 kg), and the performance will be the same Rubber, springs or air mounts don’t do that Fiberglass is made inKINETICSTM Control of Vibration, Shock, and StructureBorne